There’s something beautiful about watching a UV 3D printer at work. Watching liquid create an object out of thin air seems like the technology we could only dream about decades ago. However, that dream is a reality because of the liquid used in the process—photosensitive resin. Fully understanding what UV 3D printers are helps you understand why you need one.

There are four classifications of UV printers because each piece of technology may require a different light source or model method, whereas filament is more of a catch-all material. Let’s briefly touch on the four versions of UV 3D printers to give you a better understanding of what they do.

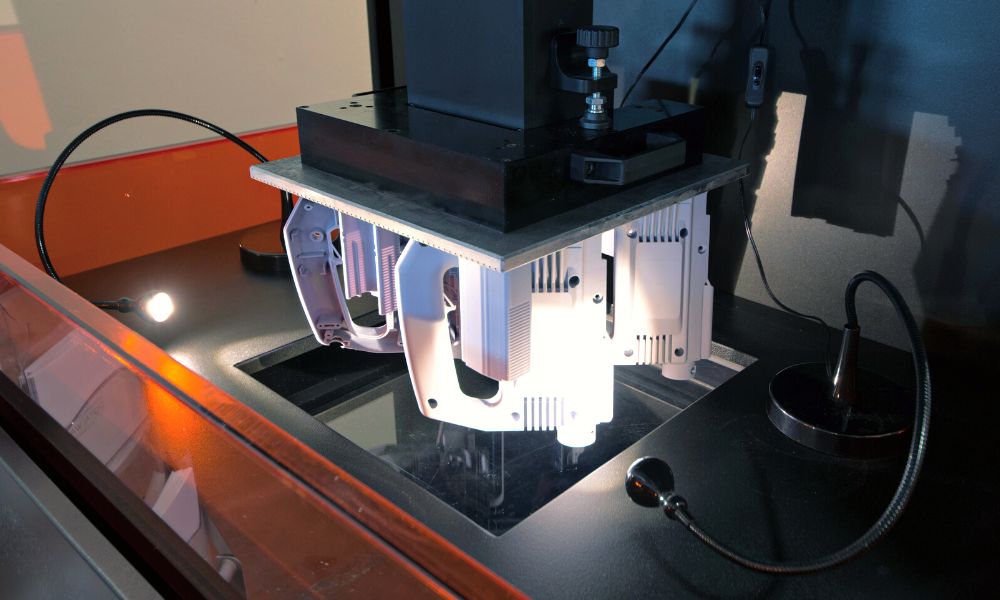

Stereolithography (SLA)

The oldest approach to 3D printing is SLA. When a UV beam meets a coating of photosensitive liquid resin, it hardens while constructing the item from multiple layers. You can print things with precise details thanks to SLA.

SLA is not ideal for larger items since it typically has smaller build plates. Plus, SLA printers can take a while to finish because they wash the items with a solvent before the process begins.

Digital Light Processing (DLP)

If speed is paramount for your printing jobs, a DLP 3D printer is your best bet. DLP takes just a few moments to print a sheet of tough material and transfer it so that the next layer can generate promptly.

The excellent printing rates result from this light source’s ability to promote the quick hardening of resin. DLP is a reliable technology that regularly generates high-resolution prototypes and enables you to employ less expensive materials for elaborate products.

Liquid Crystal Display (LCD)

A comparatively recent technique is LCD 3D printing. LCD is a less expensive alternative to DLP and stereolithography. The ability to simultaneously cure a complete resin layer makes it comparable to DLP. However, LCD employs a collection of UV LEDs as a light source instead of DLP.

To guarantee that only certain regions of the resin exist in the layer, the printer employs an LCD to selectively mask the UV radiation. Since the mask has more accessible pixels due to the greater LCD density, it may produce components with better resolution and clearer pictures.

Polyjet

Like conventional inkjet printers, PolyJet 3D printers develop drops of photopolymer plastic rather than ejecting bits of ink. A print head travels over the build platform as it ejects resin droplets onto it.

A releasable gel-like support material works well with this 3D printer to create more intricate shapes, considering the print heads may also combine different materials to produce special qualities and hues.

After learning what UV 3D printers are, you should be chomping at the bit to get one for all your 3D printing tasks. 3D Printers Depot can happily supply you with the best resin UV 3D printer! And if you find one at a lower price, let us know. We’ll ensure you get a quality printer at the lowest price possible with our price matching!