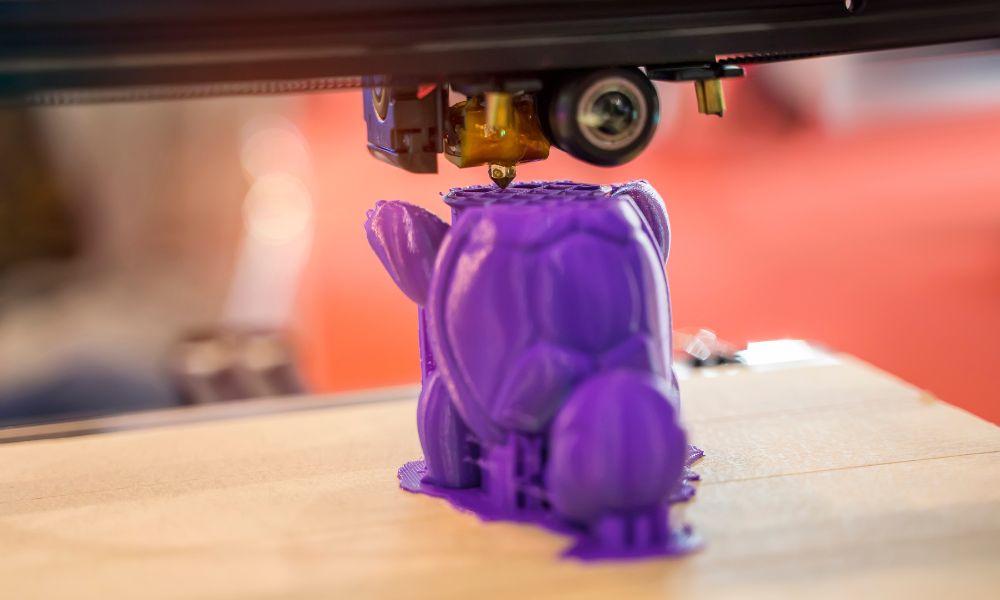

3D printing technology has come a long way over the past few years. This innovative printer allows users to create three-dimensional objects with complicated shapes and designs. However, not all printed objects come out looking perfect.

The top layer of a 3D-printed object is the first thing many people will notice, and if it comes out shaky, it can ruin the final product. This brief overview of 3D printing top layers will educate you on why it’s important and how it affects the overall result.

What Are Top Layers, and Why Are They Important?

The top layers in 3D printing refer to the final few layers the printer lays down when creating an object. Think of it like icing on a cake. This layer is what you see and touch, so it needs to be smooth and neat.

Getting it right is a delicate undertaking. Inadequate material temperature or hasty printing may result in a surface that appears irregular or textured. Therefore, meticulousness is essential when 3D printing the uppermost layers.

The Types of Top Layers

There are several types of 3D printing top layers, each with characteristics that impact the final print’s appearance and durability.

Solid Top Layer

As the name suggests, this is a complete, unbroken material layer. It gives your print a smooth and finished look, like a polished stone surface. This type is ideal for items that need a sturdy, protective outer shell.

Infill Top Layer

This variety employs a patterned upper layer like a grid or honeycomb. This results in a lighter, less material-intensive print, but it lacks the refined appearance of a print with a solid top layer.

Gradient Top Layer

This is a more advanced type of top layer that gradually changes its structure from solid at the edges to infill toward the center. This gives you the best of both worlds—a protective shell on the outside with a lighter, less material-intensive center.

Glossy Top Layer

This sort of top layer imparts a lustrous, reflective finish after printing. It may not be as durable as the solid upper layer, but it’s an excellent choice if you desire a more visually arresting effect.

Remember that the kind of top layer you choose will influence the final appearance and durability of your 3D print.

Tips for Achieving Great Top Layers

First, ensure your printing speed is exactly right. Too fast might result in scratchy layers, so slowing down can help. Second, you must maintain an ideal temperature. Too hot or too cold temperatures might degrade the material’s quality. Third, selecting the proper sort of top layer is critical. Different projects may need different layers, so make an educated selection depending on the demands of your project. Finally, keep in mind that repetition breeds perfection. The more you print, the greater your understanding of the printer and material, resulting in superior top layers over time.

The top layers in 3D printing are critical to the manufactured item’s final quality and look. Choose the appropriate kind of top layer and optimize the printing parameters to obtain the required finish.

We hope this brief overview of 3D printing top layers helps you achieve those smooth top layers with your resin UV 3D printer from 3D Printers Depot. With our collection of 3D printers and accessories, your imagination can come to life.