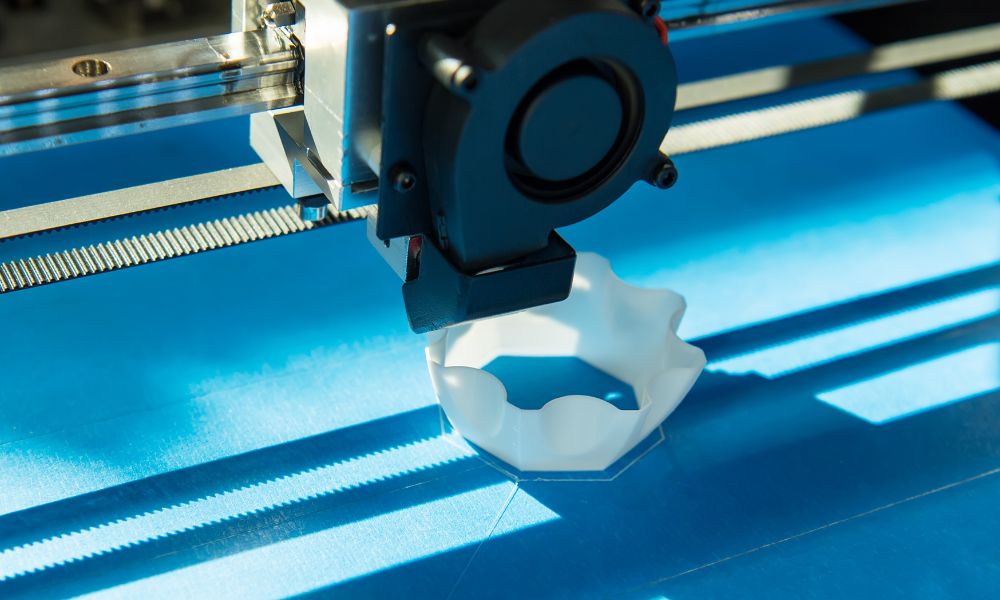

If you’ve enjoyed working with a 3D printer, you know how remarkably accurate they can be. A key component of their precision is due to curing. We want to explain curing and how it works in 3D printing so you will understand its importance for the final product.

The Curing Process

Many 3D printing experts will mention “curing” when working on a project; they aren’t talking about finding vaccines for illnesses or putting patients through physical therapy. Curing in 3D printing means applying UV light and heat to strengthen and stabilize images printed in 3D. Curing is paramount for Stereolithography (SLA) 3D printing, as it employs UV-sensitive resin.

Light curing 3D resins causes the formation of new chemical bonds inside the 3D-printed object. It also strengthens preexisting bonds. As they occur, the material gains strength, stability, and stiffness. A curing device or natural sunshine may provide the UV light necessary for post-curing. However, UV curing in direct sunlight is less efficient, and curing time might vary depending on the weather.

Factors Affecting Curing

A trio of factors involved in post-curing may throw you a few curveballs if they aren’t conducive to curing, and material type is the first.

Certain light wavelengths are optimal for maximizing the mechanical qualities of resin compositions. Many kinds of materials are available, such as Grey Pro resin, stiff resin, and regular resin.

The size of the project also plays a critical role in the effectiveness of curing. If your 3D pieces are complex or your project is big, you will need a curing machine that delivers equal exposure. These models have a spherically balanced light source and a revolving turntable. The features provide uniform curing over the whole 3D print. A machine that uses heat and light to speed up the process may be necessary for big projects.

Tolerance may be more generous if the application does not need high precision. In these situations, you may use a standard curing solution.

How To Cure

As explained earlier, curing is a two-step process of applying heat and using light. Your 3D print’s temperature will increase the kinetic energy of the resin molecules, which will cause them to move. Some post-curing chambers rotate the 3D pieces while applying heat, guaranteeing uniform exposure.

Heat prepares the polymers for cross-linking, but the photons from the light do the real work. Reactive groupings near a light source will cross-link with one another. The polymers become more robust as a network of cross-links forms and the material’s mechanical characteristics improve.

Applications that need exact measurements call for specialized curing compounds. The printer modifies the print job in advance to account for the shrinkage during the curing process. So long as you use the right printer with the right curing unit, you will obtain a 3D item with precise dimensions.

When working with a resin UV 3D printer from 3D Printers Depot, you should know what curing is and how it works in 3D printing to hone the craft. You can see the magic for yourself with one of our efficient 3D printers!