Print jobs from dual extender 3D printers can be the pinnacle of precision and innovation. Yet, those compelling designs sometimes fall short of our expectations due to nuances in the printing process. This article catalogs essential tips you can’t afford to overlook for quality dual extender print jobs.

Understand Your Printer Settings

Your printer’s manual and the settings screen are your best friends. Delve into the specifics of what each setting does. A minor tweak in acceleration can make a significant difference in the layer-by-layer precision of your prints. Learn the impact of changes like retraction speed and distance, outlining, and more. This attention to detail often separates the OK prints from the exceptional ones.

Choose High-Quality Filaments

Your prints are only as good as the crafted material, yet many underestimate the importance of filaments. Opt for high-quality filaments from reputable suppliers. Understand the properties of different filaments—PLA, ABS, PETG—and select the one best suited to the purpose of your print. High-quality filaments lead to hardy, polished results that require less post-processing.

Calibrate Your Print Bed

A level bed is foundationally crucial for your 3D prints. A thorough calibration ensures the first layer adheres properly and evenly, which is vital to print quality. Invest in a digital multimeter for best results. Remember, a calibrated bed isn’t a one-time job; it requires periodic checks and adjustments.

Optimize Layer Heights

Layer height directly affects the resolution and smoothness of the final print. It’s a balancing act between print speed and detail. While larger layer heights mean faster printing, it might not be the best option for intricate designs. Smaller layer heights allow for finer details but will generate more print data and, thus, longer printing times.

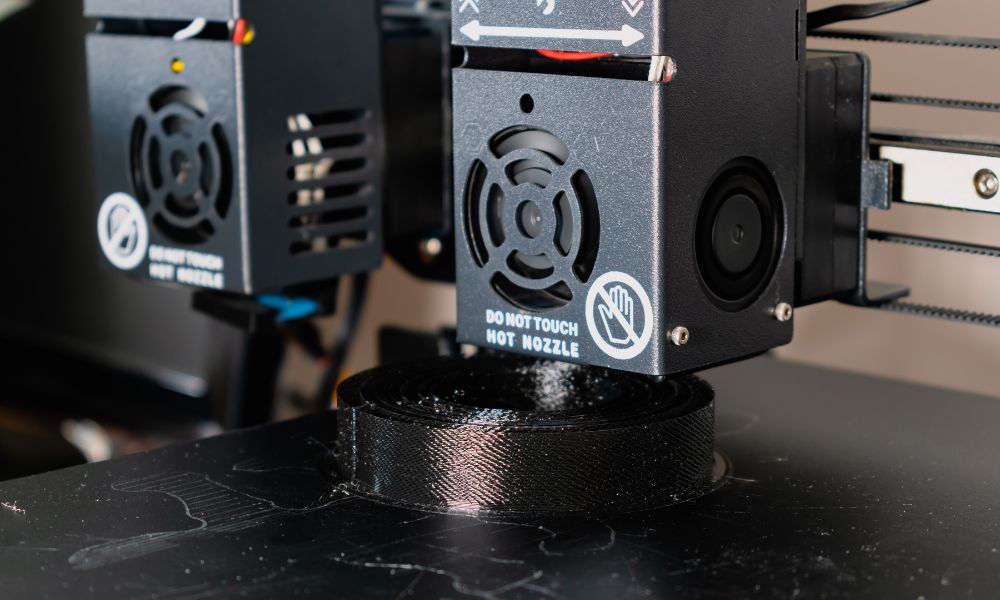

Check and Adjust the Nozzle Temperature

Controlling the temperature of your nozzle is pivotal for quality prints. If it’s too cool, the layers won’t bond properly; if it’s too hot, you’ll get stringing and blobs. Consult the filament manufacturer’s recommendations, and always monitor the temperature during a print. Note any fluctuation and adjust the settings to maintain a stable flow.

Regular Maintenance and Cleaning

Preventative maintenance is key to a long-lasting printer and to consistently producing high print quality. Clean the extruder and hot end regularly to avoid clogs, replace worn-out parts, and keep the whole machine literally and metaphorically well-oiled.

Test and Iterate for Perfection

Finally, don’t let a failed print get you down. Each one is a learning experience. Use failures to analyze what went wrong, make adjustments, and test again. This iterative approach is the pathway to perfecting your dual extender 3D print jobs.

You won’t find the formula for exquisite 3D prints in shortcuts but in the compounded effort of detail and continuous tweaking. By adhering to these foundational quality tips, every dual extender print job is an opportunity to discover new heights of quality and finesse.

Find your next high-quality independent dual extender 3D printer at 3D Printers Depot. You’ll discover various models and brands that will take your hobby or printing shop to the next level.