Wondering how to level up your 3D printing game with a dual extruder upgrade? It’s a decision that can significantly enhance your printing experience, but choosing the right one for your needs is crucial. Before you purchase a dual extruder, here are the key factors to consider.

The Dual Extruder Difference

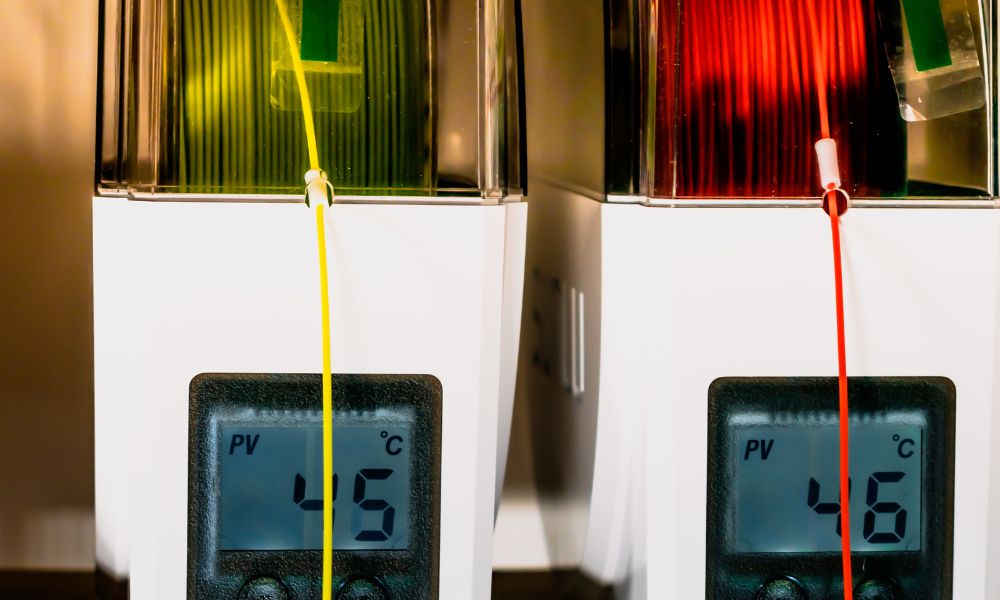

Dual extruders can be a game-changer in 3D printing. Traditionally, 3D printers operate with a single extruder, which means you can print with only one material or color at a time. A dual extruder setup allows you to print simultaneously with two different materials or colors. This flexibility opens the door for more complex and versatile prints, enabling new designs and capabilities that a single extruder can’t.

Dual Extruder Advantages

When you have two extruders at your disposal, you’re doubling your productivity and broadening your horizons creatively. Dual extruders can achieve a blend of materials, such as combining rigid and flexible plastics, which is impossible with a single extruder.

For models with intricate support structure needs, soluble filament alongside your print material makes post-processing a breeze. For commercial applications, the ability to highlight details with different colors without pausing prints is a sweet spot for marketing prototypes or personalized items efficiently.

A Spectrum of Possibilities

Integrating dual extruders is an optimal choice for flexibility. What’s more, the speed at which you can complete these jobs is usually faster than printing the same object twice with a single extruder. It’s also a relief for complex prints that demand layering—and we’re not just talking about the relief on your end, but the quality in the layer on your models.

Assessing Printer Compatibility

Adding a dual extruder to your 3D printer must harmonize with your existing setup. You want to ensure compatibility from a mechanical standpoint and with the electronics and software control. Upgrades should fit seamlessly, avoiding any printing abnormalities or malfunctions.

Software Synergy

Like any electronic device, the extruder works best when the software has caught up. Ensuring your chosen dual extruder has robust support from popular slicing software like Cura or Simplify3D is essential. You want to explore the depths of dual extrusion, enabling innovation rather than slowing down your progress.

Financial Print

The breakthroughs with a dual extruder can echo in your budget. While the initial investment may seem steep compared to a single extruder, the long-term savings can be notable. It’s a balance you must calculate.

Durability and Longevity

Investing in a quality extruder usually pays off in longevity. Cheaper models may be a short-term solution, but they often compromise print quality and reliability. Consider the cost beyond the price tag, factoring in the cost of maintenance, filament, and potential savings.

Deciding on a dual extruder for your 3D printer setup is a step toward broader horizons in your printing projects. With the right approach, you can find a dual extruder that fits your requirements like a mold, ready to cast your creative vision into tangible prints.

Are you looking for the best place to buy 3D printers online? 3D Printers Depot is the spot! Browse our expansive selection of printers today.