Science and technology are integral to additive manufacturing, and some of the most helpful facets hearken back to things you learned in grade school. The answer to why temperature resistance is important in resins comes down to viscosity and the free-flowing nature of materials.

Why Consistent Temperature Is Vital

Temperature is critical to making the resin react because it doesn’t require as much energy to cure it. Heated resin flows freely, giving it more room to interact with other hot molecules. Most resins thrive when temperatures are above 75°F because it creates a better reaction. If the temperature is below that, you can expect poor printing results.

What can make temperature and the art of 3D printing challenging is when the environment outside plays a role. For example, if you print something for a holiday party in December with the room being precisely 76°F, you may have a perfectly curated holiday ornament to show off.

Fast forward to the heart of summer—you may not change anything else on the printer, but the room is warm. If that’s the case, you will ruin the prints by overcuring them. There isn’t a one-size-fits-all type of setting if the temperature continues to fluctuate.

In summary, the more resistant your resin is to temperature, the more wiggle room you’ll have.

Avoiding Viscosity

The next part of the discussion is the viscosity of the resin. Let’s take the most elementary example to understand better how temperature affects viscosity—water. As is, water isn’t viscous whatsoever, but when it’s cold, the temperatures can affect how the resin cures. When resin gets cold, it hardens and thickens, making it more difficult to print.

Free-flowing, heated resin is much easier to work with. The build plate breaks away from the FEP film at the end of each layer. To begin a new layer, the resin must flow back into the old one and fill the void.

Opting for resting time allows the resin to recuperate and find its flow. Once rested, the build plate descends, removing everything except a thin resin coating. If the resin is more viscous, you can extend the waiting time to avoid dealing with thickened material.

Tips for the Trade

There are some helpful tips to remember if you’re still confused about how temperature can affect resin.

- Do not open the printer while printing if there’s a wide gap between the interior and exterior temperature.

- Get an additional heater to keep the temperature consistent throughout the printing process.

- Do not pour cold resin while it’s printing. Preheat the resin as if it’s a baby’s milk bottle beforehand.

- If you heat the resin, it must be at a constant temperature. Don’t add hotter water or let it sit in the water for too long.

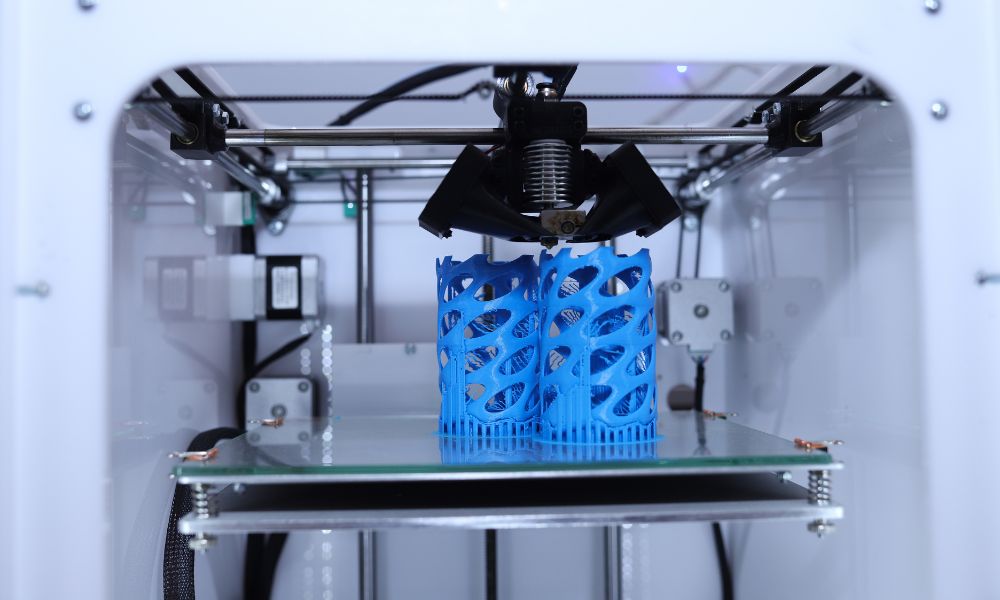

Understanding why temperature resistance is important in resins enables you to create the best print imaginable. When you have an independent dual extruder 3D printer from 3D Printers Depot, you will see what perfectly temped resin can create before your eyes.